Testing the STORM Controller in demonstration sites

The STORM controller has already been demonstrated in existing networks: an innovative combined district heating and cooling network in Heerlen (The Netherlands), and a typical 3rd generation district heating network in Rottne (Sweden). Implementing the STORMcontroller in these thermal networks has to improve their efficiency. To connect a DHC system, the STORM controller was digitally linked to the control systems of the participating buildings and the production and distribution system.

This link can be established using the following:

a) sensor override technology

b) gateway solutions, including building automation

c) full integration with an existing data management system

Both demonstration sites are operational and subject to constant changes during the course of the project, such as extra connections, changing thermal energy demand by customers, etc. This way, it is possible to obtain reference data for the evaluation of the STORM controller performance.

Contact us to talk about the possiblities

Use Case 1: Mijnwater, Heerlen, the Netherlands

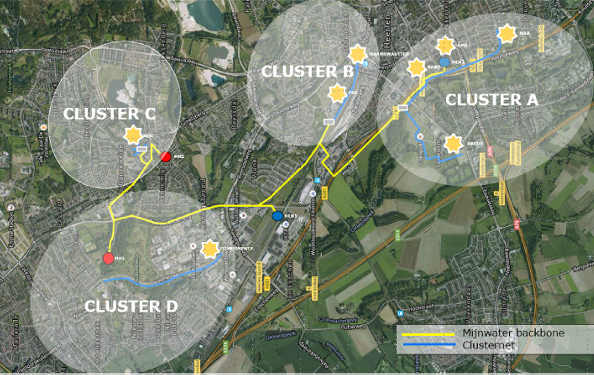

The Mijnwater DHC system in Heerlen is an ultra-low temperature 4th generation DHC grid connected to geothermal storage in the mine water reservoirs from abandoned coal mines. At the moment the total connected surface amounts to 177,291m² with a wide variety of owners and buildings. Originally, the Mijnwater system just aimed to gain geothermal energy from the mine reservoirs. The system has, since then, evolved into a smart DHC grid, organized into clusters of buildings. This upgraded Mijnwater grid exchanges thermal energy provides additional buffers and is fed by multiple renewable sources.

Each building is connected by a decentralized thermal energy station, where the temperature demand is ensured by electric heat pumps. The heating of buildings generates cooling for data centres, stores and offices and vice versa. If an imbalance between heat and cold demands occurs in the cluster grid, the Mijnwater backbone transfers this residual thermal energy to other clusters or at the end to the mine water reservoirs. The thermal energy flows are optimized and controlled by a fully-automatic demand-driven process-control system.

The Mijnwater-system consists of two hot and two cold bidirectional wells. These wells are connected by means of a pipeline system (the so-called backbone) through which, depending on the demand, mine water flows. The thermal energy exchange with the clusters takes place through heat exchangers in the cluster installations. At the moment there are three operational cluster grids (A, B and C) while the development of cluster D is in progress. The cluster grids are conventional two-pipe systems to which the buildings are connected.

Each building has its own thermal energy station with heat pumps. As a result, there is no central thermal energy plant in the grid. In fact, the Mijnwater grid is connecting a cloud of heat pumps in buildings, which provide the right building conditions while also maintaining the temperature conditions in the grid (utilizing the back side of the heat pumps). The buildings connected to the Mijnwater system have appropriate insulation quality and/or heat emission systems such as floor heating, such that heating with heat pumps is feasible.

Use Case 2: Rottne, Sweden

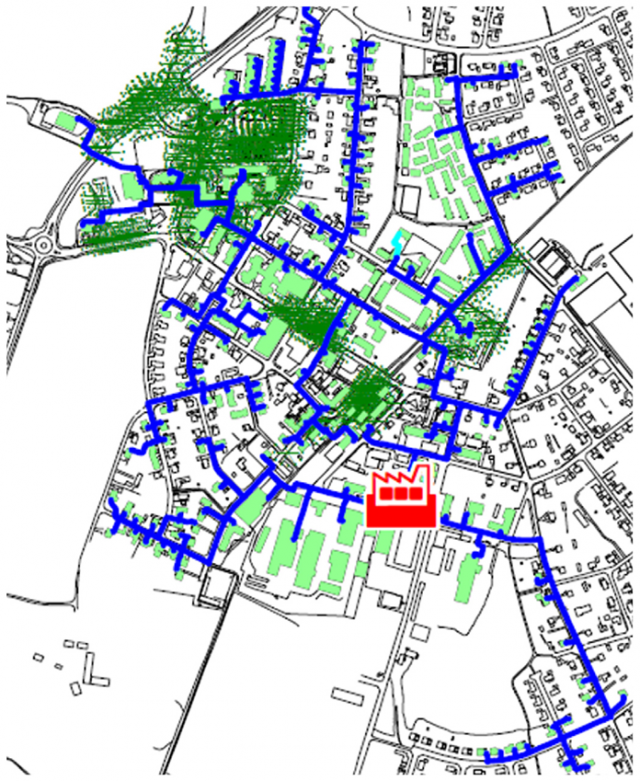

Rottne is a small city located about 19 km north of Växjö city and has 2.427 inhabitants. The district heating system in Rottne is a traditional 3rd generation system with a high-temperature distribution network. The production plant in Rottne was put into commission in September 1998 and extended in 2004. In 2012, the production plant in Rottne became completely fossil-free with the introduction of biofuels. The base load heat production in Rottne is based on two biomass boilers of 1.5 MW and 1 MW maximal capacity. The biomass originates from the surrounding forests and wood industry, consisting of wood chips, branches and peaks. An additional boiler with a capacity of 3 MW, running on rapeseed methyl ester (RME), is used for peak loads and backup. The production plant in Rottne generates approximately 12.8 GWh a year. The RME peak load boiler is activated when the heat demand surpasses the capacity of the two biomass boilers. This happens approximately when the outdoor temperature is about 1 C. During mid-winter it is common that the RME boiler kicks in due to switching outdoor temperatures.

In order to reduce the amount of heat produced with the costly RME fuel, the heat demand needs to be controlled to avoid demand peaks. There are 180 connections to the grid and the same number of substations, owned by the customers. 70% of all connections are for villas and small houses. However, 53 connections are designed for other buildings such as multi-family houses, industries, public buildings and offices. Here, the same connection can be used for several buildings, since building owners may have their own network to their buildings but obtain the heat from one substation. The district heating network in Rottne implemented the STORM controller in 2014. The targeted customer segment for the STORM controller consists of large building owners (B2B), such as non-residential building owners and housing cooperatives. The STORM system is installed in nine of the largest customer substations in the network of Rottne, representing 34% of the total heat consumption in Rottne and a heat load of 1.7 MW during an outdoor temperature of 14 C°, when the total heat load of the entire grid would be 4.4 MW. The control hardware and a basic demand-side management system were already present before the start of the project.

In the first step, the STORM Forecaster was implemented. Manual control actions were based on these forecasts. The second step was to implement the STORM Planner, using the peak shaving control strategy. This strategy has been active since February 2018 in the latest version.

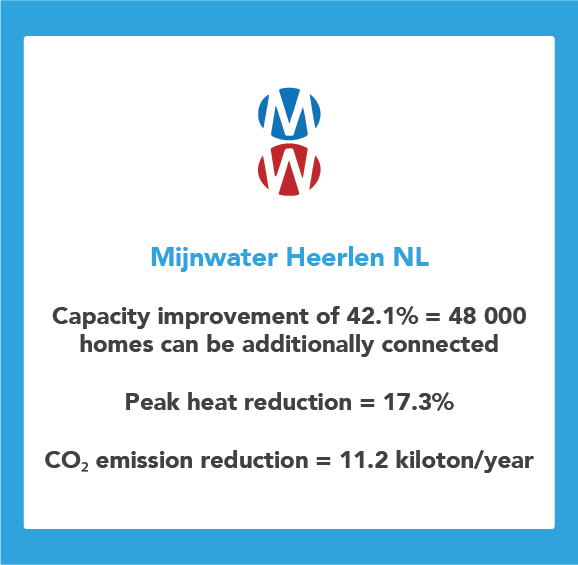

The STORM Effect

Implementing this controller in the operating system of our highly innovative 5G DHC system has led to such promising results in the areas of Peak Shaving (17,3%) and Cell Balancing (42,1%), that – due to these combined features – the capacity of our network can be enlarged by 52%.

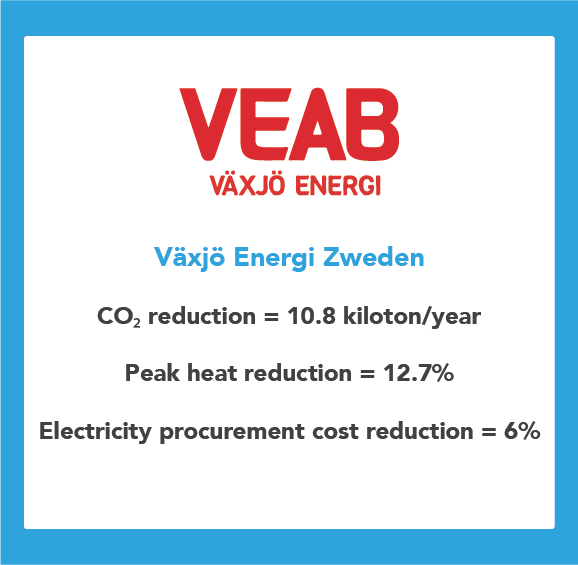

In order to remain competitive against alternative heating sources in the market, it is very important for us to keep our production costs down. The RME (bio-oil) consumption is an important key factor for us to impact, as we now, thanks to the STORM-project, can influence even further.

Download the article about our two demonstration sites

We would like to know who is downloading our document. Maybe we could have an inspiring conversation about it sometime in the future.

STORM - Testing and performance evaluation in two demonstration sites

Download our product sheet

We would like to know who is downloading our product sheet. Maybe we could have an inspiring conversation about it sometime in the future?

Product sheet: STORM District Energy Controller technology

CONTACT US TO TALK ABOUT THE POSSIBILITIES